MRO

MIRAGE III / V AIRCRAFT OVERHAULING

Established since 1974, Mirage Rebuild Factory is the sole organization in Pakistan for overhauling Mirage aircraft and associated components. It is capable to annually produce 12 aircraft and more than 10,000 components on the average. MRF is fully capable to support complete Mirage Fleet of Pakistan Air Force in accordance with OEM standards reducing the beyond country repair to near zero. Majority of the procedures exercised for maintenance are provided in the form of publications by the OEM (Avions Marcel Dassault Breguet Aviation). Aircraft overhauling at MRF is segregated into four major services:

- Aircraft Overhauling

- Aircraft Modification and Upgradation

- Aircraft Structure Repair

- Overhauling of Mirage Aircraft components

All of the facilities are certified by AS9100 Quality Management System and directed by a solid Quality Control System.

Overhauling of Airframe

Overhauling facility of Mirage airframe is a series of processes including de-painting, disassembly, ageing analysis, inspection of complete aircraft structure with the help of various NDT methods, renewal of electric looms control cables/rods and rigid pipes. All the aircraft systems hydraulic, fuel, electric, mechanic, and pneumatic are refurbished during the overhaul process, followed by on ground checks as per OEM laid down instructions in the form of work sheets. The aircraft is re-painted after assembly and released for flying after successful aerial trials. All the maintenance is documented and verified by Quality Control.

Maintenance of Aircraft Components

The components maintenance facility is established to overhaul components associated to various versions of Mirage aircraft. The facility is capable to accommodate maintenance of all the components of various aircraft systems. The services provided vary from simple bench check to complete overhaul of aircraft components. The facility is further classified into 13 different sections/shops as per job capacity. Components overhaul process involves disassembly, cleaning, inspection, assembly and final testing. Each component is inspected as per process sheets deduced from OEM prescribed maintenance manuals. Shops are well equipped with the related state of the art equipment and testers to perform the inspections of components. All the sections are manned with skilled human resource that is competent to perform the overhaul in assistance with dedicated Quality Control inspectors.

Structural Repair and Painting

Structural repair facility was established to repair and refurbish any type of structurally damaged aircraft. The facility is one of its types to recover aircraft and its structural parts damaged in accidents. Repair of fuselage frames, wing fuel tanks refurbishment, structural reinforcement modifications are the key capabilities of this facility. This facility performs the structural inspection during the overhaul inspection of Mirage Aircraft and conducts repairs where ever required. This facility is also responsible for repainting and painting of Mirage Aircraft and its components.

Aircraft Modification and Upgradation

The main aim of this facility is up-gradation of avionics systems and accomplishment of other modifications to improve the capability of Mirage weapon system. A team of skilled technicians and officers is dedicated to this facility to ensure timely execution of prototype and serial modifications. Air to Air Refuelling modification as well ROSE (Retrofit of Strike Element) have been successfully carried out by this facility on Mirage Aircraft.

Depot Level Maintenance of FALCON DA-20 Aircraft

Pakistan Air Force also operates French origin Dassault Falcon DA-20 fixed wing aircraft. Mirage Rebuild Factory has capitalized its decades of experience on French Origin Mirage Aircraft and has successfully carried out indigenous Depot Level Inspections of Falcon DA-20 Aircraft for complete PAF fleet.

Depot Level Maintenance of Agusta AW-139 Helicopter

PAF has recently modernized its SAR platform with state-of-the-art AW-139 helicopters. Owing to future MRO requirement for this rotary wing platform Depot level maintenance facility has been established at Mirage Rebuild Factory. OEM has also extended its support by certifying this facility to conduct Depot Level Maintenance of all Military variants of AW-139 helicopter. By establishing this facility MRF is contributing additional savings to National Exchequer.

ATAR Engine

Like the Mirage aircraft, the ATAR engine is also stripped down to individual components. All components undergo a thorough cleaning process to remove the contaminants accumulated during the flights on Components. The cleaning process helps in identifying the defects present on the jet engine parts. The cleaned parts undergo non-destructive inspections to identify the existing defects. Specialized radiographic inspection techniques identify even the minutest cracks existing in the parts. The radiographic machine is equipped with a robotic arm to position the part for accurate identification of sub surface cracks.

NDI techniques are available for identifying the microscopic imperfections in aircraft and engine parts. Non-destructive inspections are also aided by a semi-automated eddy current inspection machine. The machine runs its probes on the pre-defined geometry of the part and identifies the existing defects. Use of the automated probes eliminates the chances of human errors. Crack identification on the ferrous parts is also carried out by a state of the art magnetic particle inspection machine to identify the subsurface cracks.

Strict quality inspections by highly qualified inspectors ensure identification of repairable areas on the engine parts. Comprehensive repair schemes are deliberated by highly experienced engineers and parts are reclaimed through specialized processes with highest accuracy.

Over a span of more than 30 years, MRF has inducted numerous state of the art technologies for maintenance and manufacturing of aviation parts. Elaborate machining processes not only help in reclaiming the parts requiring repairs but new parts are also manufactured to service the engines. Maintaining the highest aviation standards in repairs and manufacturing of new parts is a hallmark for the factory. High velocity oxy fuel and plasma coating techniques are used for seamless build up of the parts that wear out during operation of the jet engines. Parts reclaimed by these techniques are given a new life and they get ready to be installed on the engines for the next span of their operation on the engine. Part reclamation facilities include aviation standard welding facility. This facility is used to reclaim hot section parts of different jet engines. Spot, seam and tungsten inert gas welding techniques are used to refurbish the engine parts to the highest aviation standards.

Pakistan National Accreditation Council and ISO 17025 certified precision measuring equipment laboratory is providing calibration services to keep the overhaul equipment ready to make precise measurements. PMEL calibration in done as per ISO certification standard.

Overhauling the engine accessories is a vital support setup required for the successful overhaul of any jet engine. Meeting up to the requirement, MRF has setup an elaborate system for overhauling the accessories. The process begins with completely stripping up the accessory to the basic components. The components undergo a series of elaborate cleaning and inspection steps and the defective components are identified. As per the nature of defects, either the components are repaired or replaced and then the accessories are finally assembled. The final step of overhaul is comprehensive testing of the accessories.

MRF has a series of specialized testers which simulate the aircraft operating conditions and the overhauled accessories are subjected to these conditions. During these tests stringent quality control checks are carried out to ensure compliance to the required standards and only the accessories passing all these tests are cleared for installation on the engine. Finally all these accessories and components are installed back on the engine and the engine becomes ready for test bed operation. The comprehensive setup for overhauling the ATAR 09C engine has ensured self-reliance and all the engine parts and accessories are reclaimed at the factory without any help of the foreign companies.

On the last leg of its overhaul journey, the engine is tested on the Multi Engine Test Cell. The Test cell is capable of test running various types of overhauled engines from idle to their maximum thrust in after burner settings. Close circuit cameras enable monitoring of engines with highest accuracy to determine minutest flaws or fuel leaks to ensure highest level of reliability. The test cell control room gives complete controlling and monitoring capability to the technicians running the engine. The technicians operate the engine on virtually every power setting and check all the critical operation parameters. After satisfying all the required standards, the engine is declared fit for installation on a fighter jet.

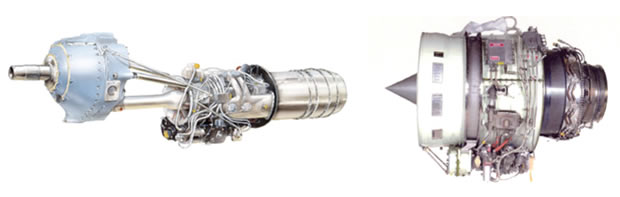

T56 Engine

The capability of the Mirage Rebuild Factory has been enhanced over the years to overhaul the engines of other military fighter, transport and trainer aircraft. In the same pursuit, a Rolls Royce certified facility has been established for overhauling the T-56 engine of C-130 aircraft. Like the ATAR engine, the overhaul journey of the T56 follows an identical process cycle for its overhauling. All the parts undergo stringent inspections and reclamation cycle before they are assembled on the rotors. Before installation on the engine, the rotors undergo specialized static and dynamic balancing to ensure vibration free running. During this operation all the weight imbalances are counterbalanced by adding weights at precise locations. Finally the engine is given a series of test bed runs to gauge its operational parameters and the results are compared to the laid out standards. During all the tests, the operators keep a close eye on the engine to look for any defects or anomalies of the minutest nature. After passing all the tests, engine is cleared for installation on the aircraft.

TFE-731 Engine

A continuous endeavor to enhance capabilities, has led to establishment of a state of the art aviation overhauling facility for TFE-731 Honeywell engine of K-8 aircraft. After thorough ground studies the first TFE 731 engine has been inducted in MRF for overhaul.

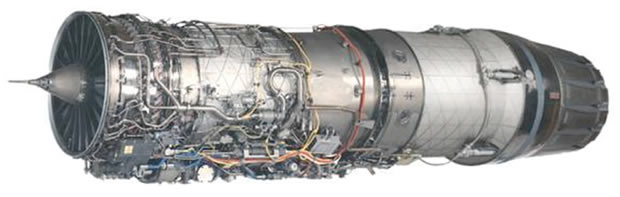

F100 Engine

In 1989, realizing the requirement of PAF to maintain newly inducted F-16 aircraft, MRF assumed the huge undertaking of establishing the overhauling setup for F100 engines of F-16 aircraft. Pratt and Whitney certified overhaul facility not only looks after all modules of F100 engine, but also upgrades 200 type engine to more powerful 220E type engine and has upgraded the entire F100 engines fleet of Pakistan Air Force.

J-69 Engine

T-37 aircraft is the main stay of the Basic Flying in PAF for over four decades. In order to meet the extensive flying requirements of T-37 aircraft, AMOF (Authorized Military Overhaul Facility) was established to repair and overhaul the J-69-T-25E engines. AMOF Status for J69 Engine overhaul was initially split in two portions i.e. Loose Parts overhaul at MRF PAC, Kamra (J69 Project) and engine assembly / disassembly and testing facility at PAF Academy, Asghar Khan. Subsequently, all the available efforts were put in to shift the complete scheduled overhauling of these engines at MRF PAC Kamra.

UPAZ

UPAZ is an external pod of IL-78, used for air to air refueling. Initially there was no 2nd or 3rd line maintenance facility available with PAF. In January, 2017 first UPAZ inducted for trial refurbishment at Engine Group, MRF and refurbishment process was developed in line with existing methods for engine overhaul. The trial refurbishment was successfully completed with indigenous efforts by MRF team during which a total of approximately 400 parts were serviced.

In addition to above MRF was also tasked to undertake trial manufacture of UPAZ pod tester AK-16 which was not easily available from foreign sources and also had a high price tag. Drawing reference from the original tester, MRF reverse engineered the circuit and mechanical design. Based on the same, a replica of AK-16 was indigenously developed and has been successfully correlated in performance with the original AK-16 tester.