GENERAL ENGINEERING SERVICES

1. Avionics System Design / Development

Avionics System Design and Development department of APF was conceived to accomplish indigenization in the domain of avionics systems. Since its inception, the department has undertaken indigenous development of multiple avionics systems from initial concept design to aerial qualification. Salient products delivered to PAF include Up Front Control Panel, Avionics Activation Panel, Audio Control Box, Digital Audio Control System, Smart Multi-Function Display, Data Transfer Unit and IFF transponder / interrogator for airborne platform.

The department is internationally certified as per AS-9100D (Design and Development Clause 8.3). The development work is undertaken as per applicable Aerospace Military Standards and type certification of each product is acquired through PAF Airworthiness Certification Agency. Core competencies of the department include: -

- Embedded System Design

- Panel and Chassis Development

- Rapid PCB Prototyping

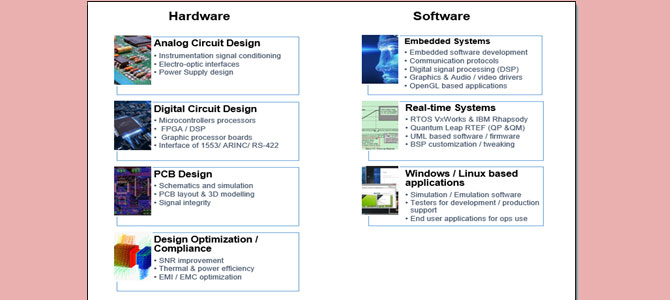

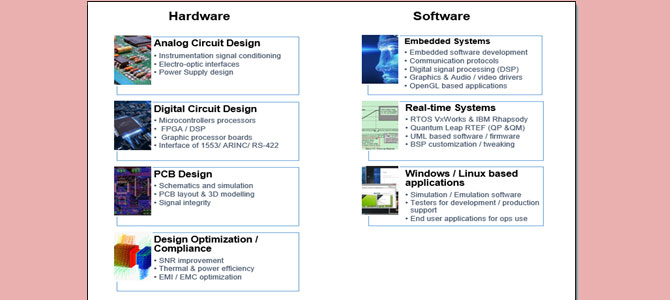

1.1 Embedded System Design

The department specializes in delivering custom embedded-systems based solutions (encompassing both hardware and software) relying heavily on innovation, creativity and cutting-edge technologies. A stage-wise development process is followed starting from feasibility study to virtual and physical prototyping. Since, embedded systems are technology-independent, most appropriate technological alternatives are sought in order to achieve customer satisfaction.

1.2 Panel and Chassis Development

The department specializes in the development of mechanical housing, chassis, NVIS compatible backlit panels and Human Machine Interfaces through state-of-the-art CAD modelling tools. The systems are designed to cater for heat dissipation, EMI/EMC management and Environmental Stress Screening. The developed systems are compatible with NVGs during night operations and provides better HMIs to comply with cockpit ergonomics of fighter aircraft.

1.3 Rapid PCB Prototyping (RPP)

The in-house RPP setup specializes in designing schematics/ layout and fabrication of PCBs for prototype development. The facility can manufacture multi layered PCBs and ensures fast, verified and error free delivery to the design engineers for validation of their hardware designs in time compressed environment. The professional software tools are used which have vast component libraries with state of the art 3D graphics and offer accurate PCB 3D modeling with high speed and advanced layer stack up options. The RPP team also has vast experience in designing of EMI/EMC and impedance controlled PCBs which meet the criteria of Avionics system specifications and aerospace standards.

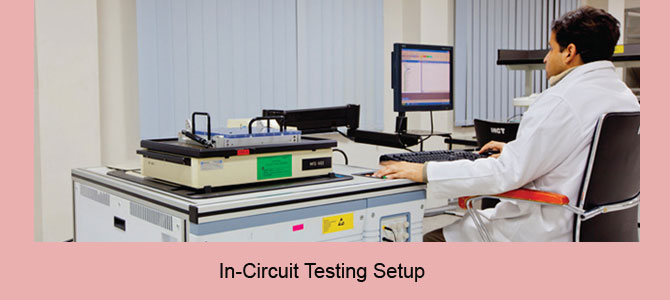

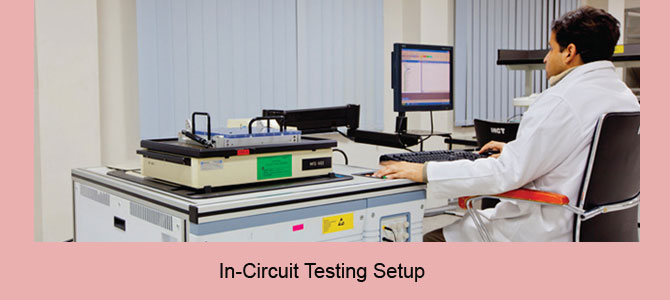

2. Avionics Testing Services

Generic Testing Facility is available for test solutions development of Digital, Analog, RF / Microwave and power supply modules of avionics systems. Based on Test Data Requirements (TDR) provided by OEM (Original Equipment Manufacturer), a significant number of test solutions have been developed on the generic test stations for multiple type LRU (Line replaceable Unit) and SRU (Shop Replaceable Unit) of various avionics systems.

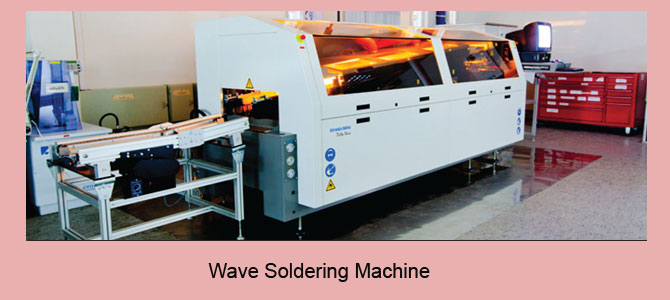

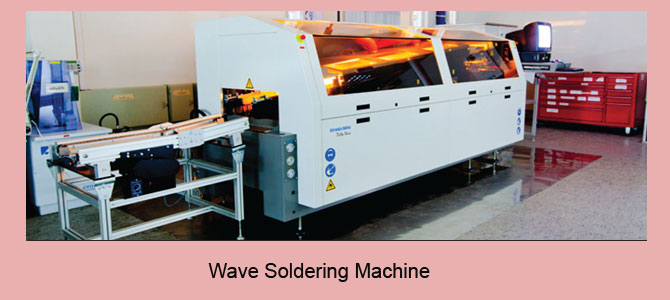

3. Avionics Production Services

PCB stuffing of both Surface Mount Technology (SMT) and Through Hole Technology (THT) components is carried out at APF generic production facilities which includes automatic SMT stuffing line, THT assembly line, optical inspection, X-ray inspection, PCB treatment (PCB Washing, Ionic contamination testing, Conformal coating).

Comprehensive PCB assembly services in abovementioned categories are being provided to valuable customers while adhering to IPC standards in commercial and military domains.

4. Environmental Stress Screening Services

ESS testing ensures that a newly designed avionics system meets the operational requirements of the airborne platform. A series of ESS qualification tests ensure airworthiness of an avionics system under extreme operational conditions. ESS testing is an important element of the overall qualification process of an avionics system. ESS equipment to conduct Mil Std 810 D compliance testing / qualification is available at APF.

4.1 Available ESS Qualification Equipment

The department specializes in delivering custom embedded-systems based solutions (encompassing both hardware and software) relying heavily on innovation, creativity and cutting-edge technologies. A stage-wise development process is followed starting from feasibility study to virtual and physical prototyping. Since, embedded systems are technology-independent, most appropriate technological alternatives are sought in order to achieve customer satisfaction.

- Thermal Climatic Chamber: Temp Range From -70°C to +180°C, Temp Velocity= 20° C

- Thermal Altitude Chamber: Temp Range From -70°C to +100°C, Altitude Range= 1 Mbar

- Thermal Shock Chamber: Temp Range From -80°C to +220°C, Temp Velocity= 40° C

- Thermal Humidity Chamber: Temp Range From -70°C to +180°C, Humidity Up to= 98%

- Vibration System : Max Gs= 110g, Frequency range= 5 to 2300 Hz, Random, Sine, Shock